Gas Network Survey Vehicle - NT10i

NT10i

Gas Network Survey Vehicle

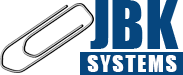

The NT10i makes it possible to monitor gas networks along the route of a car equipped with it. The NT10i works with one of the best available and proven technologies. The selective laser measuring cell detects very small concentrations of CH4 in a fraction of a second. Dedicated software with mapping and geolocation functions provides accurate GPS data for each detected gas leak point. The easy-to-use equipment meets all gas operators' requirements for performance, reliability and traceability.

MEASUREMENT:

The laser transceiver is tuned to the methane absorption wavelength.

The frequency of the laser is selected so that it does not interfere with propane, butane, hydrogen, car exhaust, water vapor present in the air.

Sampling:

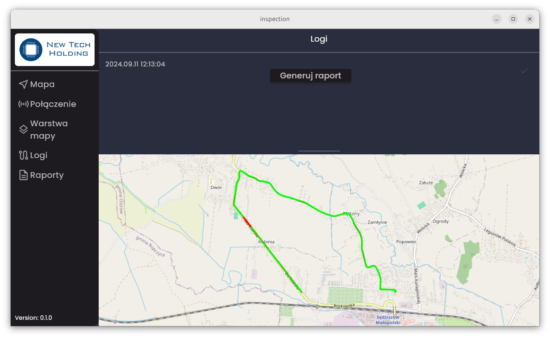

A set of hoses mounted on the front of the vehicle draws gas samples from the ground surface into the measuring chamber.

A high-performance suction pump allows gas samples to be transferred to the entrance of the measuring chamber in less than 1s.

The total response time of the measurement system from the moment of sampling to the delivery of the measurement result on the on-board computer screen does not exceed 1.5s

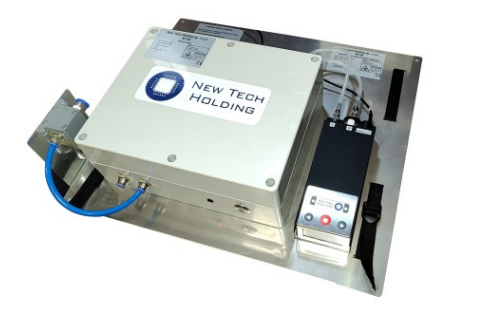

SOFTWARE:

Proprietary software automates the measurement process.

The ability to load company maps with gas pipelines plotted on them makes it easy to maneuver the vehicle to get as close as possible to gas pipelines.

Vehicle route control provides maximum inspection coverage and multiplies the possibility of detecting a gas leak.

SAMPLE INTAKE:

8-section sampling line

8-section sampling line

System components built in for easy access

The sampling system is protected by a hydrophobic filter, blocking the flow of water into the measuring cell

The air flow is verified by a measuring sensor built into the suction line

Once the systems are up and running, a set of self-tests verifies, among other things, the patency of the sampling lines

GPS:

GNSS receiver, 4-frequency

Support for GLONASS, GALILEO, GPS, support for fixed base stations

Roof-mounted antenna significantly improves the quality of the received signal

| Measurement range | 100%Vol (or 0-40000 ppm) |

| Protection degree | IP66 |

| Operating temperature | from -10˚C to 40˚C |

| Operating humidity | Up to 95% Rh |

| Response time | 1,5s |

| Language | Polish |

| Emergency warning of the device | supported by dedicated software |

| Data transmission to devices | default communication between measuring unit and software - Bluetooth |

| Data transmission to external devices | TCP over Internet, Ethernet to any external device from a dedicated computer with software |

| Readout device | Anyone. Software compatible with PC or Android. |

| Software | Dedicated, author, Polish language, lifetime license |

| Built-in GPS receiver | High-performance GPS receiver, antenna with 1.5m cable, with magnetic gripper |

| Power supply | 12V power supply from the car's installation |

| User manual | In Polish language |

| ATEX certificate | Yes, for measuring device |

| Technical support | Email and telephone technical support from the manufacturer. |

| CE Declaration of Conformity | Yes |

| Warranty service | The service repair period of the device is up to 14 calendar days from the date of written notification by the Ordering Party. The Contractor shall provide a guarantee of access to service of the device in the territory of Poland for a minimum period of 10 years from the receipt of the subject of the Order. Acceptable other arrangements with the customer. |

| Warranty | 24 months or as agreed |

| Field measurement range | Measuring lane - 8 meters, conducting measurements when driving up to 40km/h |

| Corrosion resistance | All elements of the system made either from plastic elements or from steel covered with a layer of protection against corrosion |

| Overall dimensions | 35x40x15cm |

| Weight | 5kg |

| Measurement width | 3 meters per side (the entire controlled lane is 2 x 3m + car width) |

| Selectivity of measurements | Full selectivity of measurements for methane - TDLAS technology |

| Resistance to changes in operating temperature and mechanical vibration. | Yes |

| Protection against ingress of dust o moisture | Double filtration system to prevent absorption of moisture and penetration of fine dirt |

| System self-monitoring | Automatic system verification system for zero, sensor and vacuum control of the sampling system |

| Auto-cleaning of the sampling system | Automatic gas cleaning system |

| Type of suction tube installation | Standard installation of 8 suction tubes in the front bumper. For SUW cars equipped with front grab bars, it is permissible to install a bar integrated with hoses. |

| Cleaning up the sampling plant | Installation equipped with an additional connection point for feeding compressed air to clean the installation from water and dust |

| Maximum vehicle speed during measurements | 40km/h |

| Navigation | Navigation using GPS, based on a digital map |

| Registration of the car's location | Based on GPS readings, accuracy less than 2m, DGPS correction support. The system reads the date, time, coordinates and speed of the car based on GPS and the measurement value from the measuring instrument |

| Type of GPS receiver | 2 frequency receiver, support up to 36 channels, receive signals from four basic GNSS satellites |

| Antenna installation | Antenna mounted in such a way that it is not exposed to external stimuli |

| Road map primer | Support for OpenStreetMap |

| Software | Online work. Among other things, analysis of the distance of the vehicle from the gas network, automatic classification of the zones of the inspected gas networks. |

| Import/export | SHP standard support. Overlay of gas network maps on the main map. |

| Documentation of the course of inspection of gas pipelines | The system automatically writes data to the database: date, time, vehicle speed, geographical coordinates, gas concentration. Tabular data is made available via CSV option XML-GPX and to SHP. The report is generated by default to PDF or on request to XLS or DOC. |

| Resources | |

| Brochure: | NT10i_Brochure |

| Manual User: | NT10i_User_Manual |