JBGR gas sensor sampling system

JBGR - Mutlipoint gas detection system for gas taken by hoses from remote measurement points.

The refrigerant measurement system features a unique combination of high sensitivity, wide measurement range and speed of response to the gas. Using infrared technology, the detection system is a great solution to match the customer's expectations, giving the possibility of remote communication and visualization, centralized reporting and management. Continuous gas leak monitoring is the core of harmful gas detection.

Used primarily for the detection of hydrofluorocarbon refrigerants, carbon dioxide and ammonia, this high tech system protects industries in terms of efficiency, quality, minimizing cost loss and integrity of the surveillance system. Low-level detection is extremely imporant when leaks are small, thus protectiong and alerting for immediate correctibe action so as to minimize energy and refrgerant losses.

The system has a basic 230V power supply (24VDC on request) and reinforced ASCO solenoid valves, making it ideal for installation in mobile areas such as ships transport, platforms, refrigerated vehicles. The system has EN 14624 and CE certification.

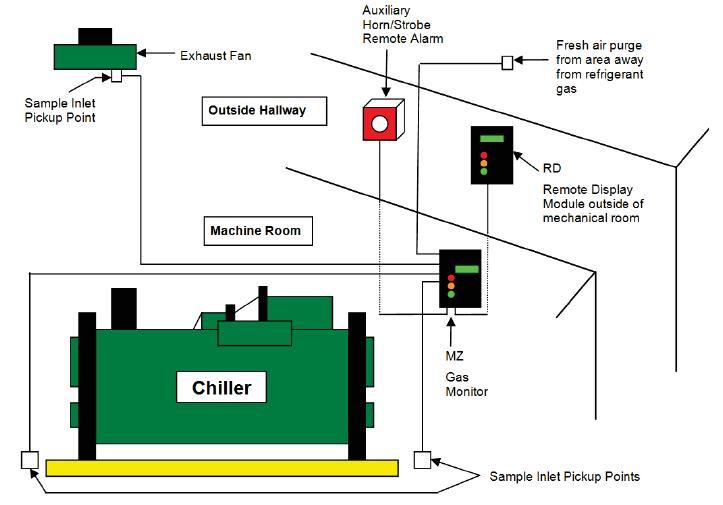

The system works by sucking in gas via built-in suction pump sequentially from remote points to the gas sensor.

Speed of response to a gas leak depends on the length of each hose used and the number of connected measuring points (hoses). The gas flow inside hose is about 1 m/s, which determines how long it takes for the leak to reach the gas sensor.

Using a splitter it is possible to duplicate measurement points within a single hose and simultaneously monitor two or three sensitive nearby points on a refrigeration system.

The JBGR control panel is available in 4, 8, 12, 16 measurement inputs. A typical solution has one or two measurement sensors mounted in the lastest NDIR technology usually measuring CO2 and a selected are conditioning gas. The system has a built-in web server, so that you can easily connect a computer with a monitor or tablet to the control panel and manage the system through a web browser. System has Ethernet and CAN outputs (optional), which allows to set up communication with another viewing or management system up to 1000m away from the control panel.

JBGR control panels can be connected to external devices on Ethener, Modbus TCP, CANOPEN protocols, making it possible to monitor a very large number of points of potential gas leakage.

Example of system installation in the machine room

TECHNICAL DATA

JBGR manual, 12-valves version

JBGR CE Declaration of Conformity