JBK is a certified provider of solutions in the field of control and automation technology.

A wide range of services, starting from consulting, pre-implementation and audit services, design and programming services, through delivery, integration, and implementation of systems, to their ongoing supervision and operation, ensures comprehensive problem-solving for target clients.

Stationary systems

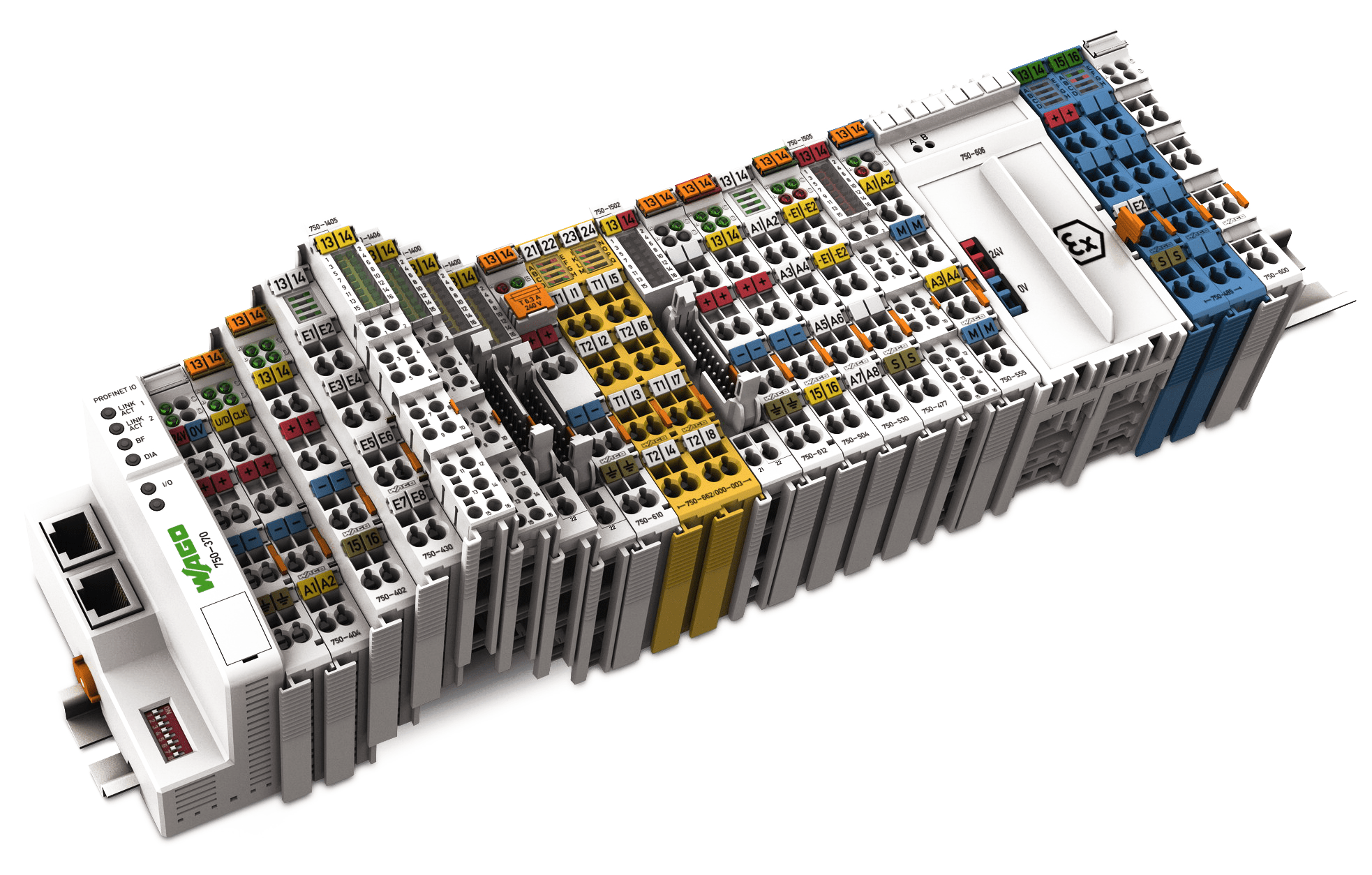

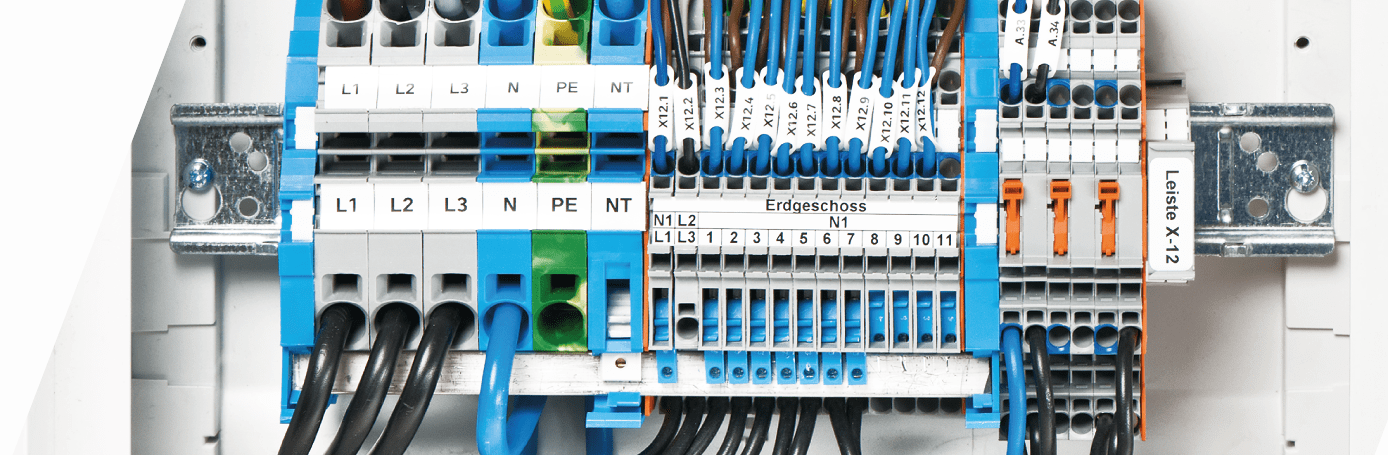

WAGO-I/O-SYSTEM is a family of network-independent input and output modules for distributed control. WAGO's relay, function, transition and surge protection modules form a range tailored to the needs of any application.

Modular network devices, suitable for any type of distributed control network, have the important advantage of creating flexible and easily modifiable automation systems. As early as 1995, WAGO presented components for the creation of field networks, enabling modular expansion of the network node as required. Since then, the system has been continuously developed and expanded with new products.

WAGO's I/O systems, electronic and interface modules, power supplies and surge protection modules are used wherever high performance and 100% reliability are required, such as in industry, process technology, building automation, as well as in areas requiring increased safety measures and hazardous areas.

AUTOMATION includes automation components based on network systems and spring clamp technology as well as electronic modules for industry, process technology and building automation.

Among the control and visualisation systems available is the dedicated Flex Room building automation system.

Mobile Systems

IFM offers a complete set of active command and control components and a set of passive components required to build command and control systems on vehicles and mobile devices.

Typical applications include agricultural machinery, construction machinery, self-propelled unloading systems, special vehicles. The technology used allows the system mounted on a mobile machine to be used without problems. The automation and control components are E1 KBA certified and MTTFd certified. This means that they have been tested and can be used in equipment and systems where the aspect of cyclic and impact vibrations and resistance to moisture, wetness and dirt are of utmost importance.

The ecomatmobile Basic controllers in modular design, are easy to install, program and also cost-optimised. In addition to pure control functions, solutions for cabling and protection are provided. A graphic visualisation module allows system messages and simple graphical elements to be displayed.

The ecomatmobile Basic controllers in modular design, are easy to install, program and also cost-optimised. In addition to pure control functions, solutions for cabling and protection are provided. A graphic visualisation module allows system messages and simple graphical elements to be displayed.

The ecomatmobile control systems platform: powerful controllers. Free programming and diverse configurations enable use in a wide range of applications.

The ecomatmobile control systems platform: powerful controllers. Free programming and diverse configurations enable use in a wide range of applications.

Distributed I/O modules for CANopen network applications. Significantly reduced wiring effort due to the mounting of the modules at the signal collection point. Free configuration of inputs and outputs allows universal use and reduces storage costs.

Distributed I/O modules for CANopen network applications. Significantly reduced wiring effort due to the mounting of the modules at the signal collection point. Free configuration of inputs and outputs allows universal use and reduces storage costs.

The dialogue modules have graphic displays, free programming in accordance with IEC 61131 and a variety of interfaces. Convenient interface for servicing and operating machines - the dialogue modules of the ecomatmobile control system.

The dialogue modules have graphic displays, free programming in accordance with IEC 61131 and a variety of interfaces. Convenient interface for servicing and operating machines - the dialogue modules of the ecomatmobile control system.

In almost all mobile machines, today's users use displays that provide information about the machine. At the same time, a camera system monitors the operating areas. Here, the new O2M camera system is used. Designed to operate under extreme conditions.

In almost all mobile machines, today's users use displays that provide information about the machine. At the same time, a camera system monitors the operating areas. Here, the new O2M camera system is used. Designed to operate under extreme conditions.

Recording diagnostic data - the basis for an efficient and cost-effective remote monitoring and service concept. Reducing service costs and downtime during failures are significant advantages of this modern technology.

Recording diagnostic data - the basis for an efficient and cost-effective remote monitoring and service concept. Reducing service costs and downtime during failures are significant advantages of this modern technology.

A solution for special applications. Converter for converting signals from sensors and actuators into signals for I/O modules of controllers or CANopen networks.

A solution for special applications. Converter for converting signals from sensors and actuators into signals for I/O modules of controllers or CANopen networks.

From analogue inclinometers or those with a CANopen interface, through inductive proximity sensors to pressure sensors for mobile applications. The sensors of the ecomatmobile series work reliably even under the extreme conditions of a mobile machine.

From analogue inclinometers or those with a CANopen interface, through inductive proximity sensors to pressure sensors for mobile applications. The sensors of the ecomatmobile series work reliably even under the extreme conditions of a mobile machine.