Digital gas sensors dedicated to distributed networks

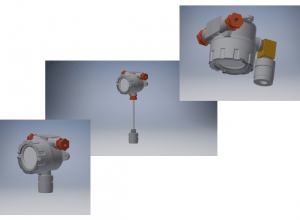

NET-EX Cyber SENSOR

The lastest ATEX/IECEx gas sensor with integrated electronics and sensor

The NET-EX sensor is a new ATEX-class solution with 4-20 mA and Modbus transmitter outputs, enclosed in a chrome-nickel housing.

An electrochemical, infrared or pellistor sensor can be connected to the electronics integrated in the housing. NET-EX is housed in a two-piece flameproof enclosure: lower part contains a chromonickel fleece filter that allows the gas to pass through; upper part contains the electronics and sensor.

The selected sensor is mounted in a special protective capsule, holding it in position to guarantee the highest performance.

The versatility of the housing and a set of protective capsules gives NET-EX the ability to fit standard electrochemical oxygen and toxic gas sensors. The NET-EX's two-piece housing allows for easy sensor replacement. The lower part of the housing has an M46X1.5 thread for easy mounting of accessories or sensor mounting. Cable connections are available with M20x1.5 threads as standard, or M25x1.5 or 3/3" on request.

The NET-EX sensor has been tested and certified in accordance with the ATEX directive.

Dust and IP-enhancing protection is available on request in the form of an additional thread-mounted adapter.

Features:

Features:

- 4-20 mA output for connection to analogue systems

- RS485 (Modbus) for operation in digital systems

- Three easy-to-read multicolour indicator lights correctly visible from a distance of several tens of metres

- Compatible with IR, EC and pellistor sensors

- The system is supplied complete with configured and calibrated sensor

- Custom designs are available on request

- Simple on-site calibration

- System management software

- Full ATEX-compliant certified flameproof enclosure.

- Power supply 9-30V DC

- available in standard, angle-head and cable-head versions.

Uniqueness of the solution:

NET-EX sensors have:

- 4-20 mA output for interfacing with legacy management systems such as BMS, SCADA, PLC

- Modbus RTU output for cooperation with any modern BMS, SCADA and PLC control units with communication over digital networks, in particular with dedicated BZ and JBSM systems from JBK.

- Visible service and alarm signals

- Protection against sensor damage by excessive gas concentration (optional)

- Setting parameters stored in the memory of the measuring sensor electronics.

The Modbus RTU output port allows:

- building extensive digital networks with gas sensors with a single line length of up to more than 1 km

- gain full control of the sensor by accessing its microprocessor

- possibility to perform remote procedures in the sensor controller, including remote sending of calibration messages

- continuous, non-modifiable and non-repudiable measurement of sensor status, including digital readout of data, alarms, errors

- collection of historical data in BMS, SCADA, PLC systems.

Safe, robust housing for a wide range of applications

- The housing, a combination of aluminium and stainless steel, is suitable for a wide range of environmental conditions

- A housing with a toughened glass viewfinder, a highly flame-retardant construction and a specially selected separator filter for the sensor chamber to dissipate the gas energy mean that the instrument retains its functionality for a very long time after the fire has started.

- The Ex "d" execution allows direct connection of equipment (control panels) from outside the hazardous area, without the need for additional material and labour costs for the installation of intrinsically safe barriers.

Ergonomics and safety

- The sensor connection cover allows the sensor to be installed separately from the distribution housing

- The distribution box is installed in a conveniently visible and accessible location, while the measuring sensor is installed close enough to the predicted gas cloud, often in a place that is difficult to access.

Standard versions:

| Detected gases | Gas code | Sensor type | Range |

| Hydrocarbons | HC | Pellistor | 0-100% LEL |

| Ammonia | NH3 | Pellistor | 0-100% LEL |

| Hydrogen | H2 | Pellistor | 0-100% LEL |

| Methane | CH4 | NDIR | 0-100% LEL (4,4%Vol) |

| Methane | CH4 | NDIR | 0-100% LEL (5,0%Vol) |

| Propane | C3H8 | NDIR | 0-100% LEL (1,7%Vol) |

| Propane | C3H8 | NDIR | 0-100% LEL (2,1%Vol) |

| Carbon Dioxide | CO2 | NDIR | 0-5000 ppm |

| Carbon Dioxide | CO2 | NDIR | 0-5% vol |

| Sulfur Hexafluoride | SF6 | NDIR | 0-1000ppm/2000ppm |

| R-134a i pochodne | R134a | NDIR | 0-1000ppm/2000ppm |

| Carbon Monoxide | CO | Elektrochemiczny | 0-300 ppm |

| Hydrogen Sulfide | H2S | Elektrochemiczny | 0-100 ppm |

| Amonia | NH3 | Elektrochemiczny | 0-100 ppm/300ppm |

| Amonia | NH3 | Elektrochemiczny | 0-1000 ppm/5000ppm |

| Nitrogen Dioxide | NO2 | Elektrochemiczny | 0-30 ppm |

| Nitrogen Oxide | NO | Elektrochemiczny | 0-300 ppm |

| Chlorine | CL2 | Elektrochemiczny | 0-10 ppm |

| Sulfur Dioxide | SO2 | Elektrochemiczny | 0-20 ppm |

| Oxygen | O2 | Elektrochemiczny | 0-25% vol |

The technology of tomorrow

NDIR (non-dispersive infrared) technology, the latest in infrared technology, combined with dedicated management electronics, enables unprecedented quality, stability and repeatability of detection.

The advantage of the NDIR sensors on offer is the practical absence of zero and maximum value drift.

The higher purchase price, over a minimum of 5 years, is more than compensated for by avoiding expensive periodic sensor calibrations.

You can find out more in the FAQ.

TECHNICAL DOCUMENTATION

NET-Ex wymiary puszki rozdzielczej

NET-EX Deklaracja zgodności CE wersja 3G

DESIGNER ZONE:

| Distribution box | NET-Ex Std | NET-Ex Cab | NET-Ex Ang |

| puszka rozdzielcza NET-Ex (dwg) | NET-EX z głowicą Autocad (dwg) | NET-EX z głowicą na kablu (dwg) | NET-EX ze złączem kątowym (dwg) |

| NET-EX z głowicą (STEP) | NET-EX z głowicą na kablu (STEP) | NET-EX ze złączem kątowym (STEP) |